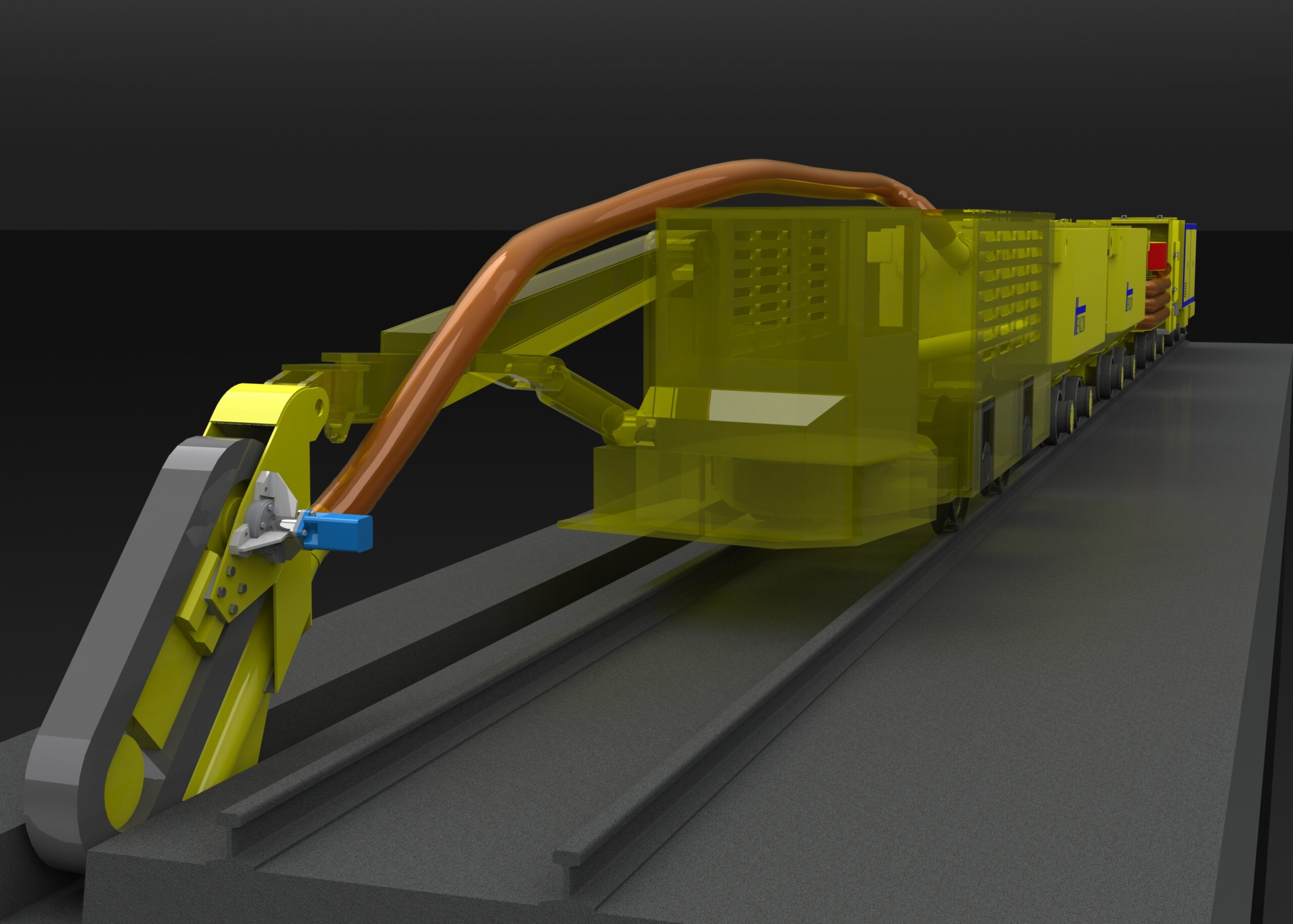

HVT-ESV_RAIL

Rail Vacuum

Cleaning spillages under conveyors and in other hard-to-access areas is a major challenge for mine and process plant cleaning crews, especially when underground.

A rail mounted vacuum unit like the HVT-ESV_RAIL allows the use of existing mine rail infrastructure, including locomotives to move the vacuum unit around the mine.

Once at the required area, the unit can be connected to an HVT mine type gravity discharge collector bin to accumulate the material and discharge it as as needed. These collectors can be mounted above conveyors, allowing the material to be put back onto the conveyor in one step without the need for further handling. This makes the process of cleaning and recovering spillages highly efficient and effective.

Using a vacuum system also minimises the further creation of dust during handling, a common by-product of cleaning spillages conventionally.

| Power | Electric | 400/525/1 000VAC |

| Supply Frequency | 50Hz | 60Hz on request |

| Motor Power | 75/90/110kw | |

| Control System | 24VDC | |

| Maximum Airflow Rating | 3 000/3 300/4 800 | m³/hour |

| Maximum Vacuum Pressure | -80kpa | At sea level |

| Suction Hose Diameter | 100mm (75kw) | 100mm & 150mm |

| Rail Track Width | Various | As required |

| Mass | From 2 500kg | Up to 3 500kg |

Note: This unit works in conjunction with a suit able Hencon VT vacuum collector bin.